Mafi kyawun Mai Kera Welding Mota da Masana'anta A China

Ci gaban Kamfani

- A cikin 2011, an kafa TTM a ShenZhen.

- A cikin 2012, Ƙaddamarwa zuwa DongGuan;Gina haɗin gwiwa tare da Magna International Inc.

- A cikin 2013 Gabatar da ƙarin kayan aikin ci gaba.

- A cikin 2016, Gabatar da manyan kayan aikin CMM da 5 axis CNC kayan aiki;Haɗin kai tare da OEM Ford Completed Porsche, Lamborghini da ayyukan Tesla CF.

- A cikin 2017, Motsawa zuwa wurin shuka na yanzu;An ƙara CNC daga 8 zuwa 17 sets.An kafa Top Talent Automotive Fixtures & Jigs Co.Ltd

- A cikin 2018, Haɗin kai tare da LEVDEO na kera motoci kuma ya kammala layin samar da motoci.An gabatar da 4-axis high-gudun CNC, jimlar Qty na CNC ya kai 21.

- A cikin 2019, Dongguan Hong Xing Tool & Die Manufacturer Co., Ltd an kafa.(Sabis tasha ɗaya) Haɗin gwiwa tare da Tesla Shanghai da Sodecia Jamus.Gina sabon dakin gwaje-gwaje na R&D don sarrafa kansa.

- A cikin 2020, Haɗin kai tare da OEM ISUZU a cikin SA; An kammala Sabis na Tsayawa Daya na RG06.

- A cikin 2021, Ci gaba tare da ingantaccen imani don ƙirƙirar masana'anta mai daraja ta duniya.

- A cikin 2022, an kafa ofishin rukunin TTM a Dongguan City, New CNC 4 axis * 5 sets, New Press * 630 ton, Hexagon Absolute Arm.

- A cikin 2023, TTM yana gina sabon shuka don duba kayan aiki da kayan aikin walda;ƙara guda 2000T latsa.

Duba Kafa & Welding Jigs Factory (Jimlar yanki: 9000m²)

Kayayyakin Hatimi & Mutuwa da Masana'antar Kaya (Jimlar yanki: 16000m²)

Bayanin Samfura

| Sunan samfur | Walda Fixture |

| Aikace-aikace | Automotive CCB, Front End, WS Spring Link, Front Bumper da dai sauransu. |

| Nau'in walda | Spot Welding, Arc waldi, (CNC/Majalisa) Kayan walda na musamman |

| Alamar Ƙarƙashin Ƙarƙashin Ƙwaƙwalwar Ƙwaƙwalwa | SMC, FESTO, TUENKERS, CKD, Maƙen hannu |

| Alamar Kayan Wutar Lantarki | OMRON, Mitsubishi, Siemens, Balluff |

| Material (Katange, Wurin Wuta) | 45# Karfe, Copper, Bakin Karfe |

| Hanyar Aiki | Robot Welding, Manual Welding, Musamman na'ura waldi |

| Hanyar Gudanarwa | Air Control (Pneumatic Control Valve), Electrical Control (Solenoid Valve), Manual, Babu solenoid bawul da ake bukata Samar da connector sauya |

| Hanyar Matsala | Pneumatic, Manual |

| Hanyar Sadarwa Tare da Waya Waya | EtherCAT, PROFINET, CC-LINK |

| Akwatin Relay Sadarwa | Wurin lantarki akwatin wayoyi, Saurin soket irin, Solenoid bawul tsibirin nau'in |

| Welding Fixture Base Type | Kafaffen ƙasa, Matsakaici/Flip Tye |

| Hanyar Bututu | Bututun Layer guda ɗaya, Bututu mai ɗaukar wuta, Bututun ƙarfe / Bakin Karfe |

| Jiyya na Fannin Fixture | Zane, Zane + Baƙar Oxidization, Tushen Zinc, Zanen Foda |

| Lokacin Jagora | Makonni 2-4 don ƙira da sake dubawa; 10-12 makonni don masana'antu bayan amincewa da ƙira 7-10 Kwanakin aiki don jigilar iska; Makonni 4-5 don shan ruwan teku |

| Mutuwa Rayuwa | Ya dogara da ƙarfin samar da abokin ciniki |

| Inshorar inganci | Binciken CMM Gwaji da Samfurori Akan Siya-Kashe Sayi-Kashe Babban Taron Yanar Gizo na bidiyo akan layi Magance Matsalolin Saye-Kashe |

| Kunshin | Akwatunan katako don samfurori; Kwalayen katako ko pallet don kayan aiki; |

Motocikayan waldakayan aiki ne masu mahimmanci a cikin tsarin kera motoci.An tsara waɗannan na'urori na musamman don tabbatar da daidaitattun jeri da haɗuwa na sassa daban-daban, sauƙaƙe walda na chassis, sassan jiki, da sauran sassa masu mahimmanci.A cikin wannan cikakkiyar bayyani, za mu bincika mahimman abubuwan da suka haɗa da kayan aikin walda na motoci, gami da mahimmancin su, abubuwan ƙira, ƙira, sarrafa inganci, da rawar da suke takawa a cikin masana'antar kera.1. Muhimmancin Kayan walda na Mota:

Na'urorin walda na motoci suna taka muhimmiyar rawa wajen kera motoci saboda dalilai da yawa: Daidaitawa: Suna tabbatar da daidaitattun abubuwan haɗin gwiwa, suna haifar da daidaito da daidaiton walda.Wannan yana da mahimmanci ga daidaiton tsari da amincin abin hawa.

Ƙimar aiki: Kayan aikin walda yana hanzarta tsarin taro, rage lokacin masana'antu da farashin aiki.Tabbacin inganci: Ta hanyar riƙe sassa a daidaitattun wurare, kayan aiki suna rage haɗarin kurakurai da lahani a cikin samfurin ƙarshe.Daidaituwa: Tsare-tsare suna ba da tabbataccen sakamako, ba tare da la'akari da matakin ƙwarewar ma'aikaci ba, wanda ke da mahimmanci don samun ingancin abin hawa iri ɗaya.2. La'akari da Zane: Zayyana na'urorin walda na motoci wani tsari ne mai rikitarwa wanda ya haɗa da yin la'akari da hankali akan abubuwa daban-daban: Model Mota: Zanewar kayan aiki dole ne ya dace da ƙayyadaddun ƙira da ƙirar motar da ake samarwa.Wannan yana buƙatar zurfin fahimtar buƙatun haɗin abin hawa.Matsayin Sashe: Madaidaicin dole ne ya sanya daidaitattun abubuwan abubuwan abin hawa daban-daban, kamar fafukan jiki, sassan chassis, da abubuwan firam.Wannan ya ƙunshi madaidaicin wuraren wuri, hanyoyin matsewa, da tsarin tallafi.Haƙuri da Daidaitawa: Dole ne injiniyoyi su yi la'akari da ƙaƙƙarfan juriya da buƙatun daidaitawa don tabbatar da cewa abubuwan sun dace daidai da juna.

Zaɓin Material: Zaɓin kayan da aka zaɓa don ƙayyadaddun kayan aiki yana da mahimmanci.Ya kamata ya zama mai ɗorewa, mai jure zafi, kuma mai ƙarfi don jure aikin walda.Ergonomics: Ya kamata a tsara abubuwan gyara don sauƙin amfani da amincin mai aiki.Wannan ya haɗa da la'akari don samun dama, ganuwa, da ergonomics yayin ayyukan walda.3. Ƙirƙirar Ƙarfafawa:

Ƙirƙirar kayan walda na mota ya ƙunshi matakai da yawa:

CAD Design: Masu ƙira sun ƙirƙiri cikakkun samfuran 3D CAD na ƙayyadaddun, suna ƙayyadaddun matsayi, daidaitawa, da maki masu matsi ga kowane bangare.Zaɓin kayan aiki: Dangane da ƙayyadaddun ƙira, ana zaɓar kayan da suka dace, sau da yawa ƙarfe ko aluminum, don gina ginin.Ƙirƙirar Ƙarfafawa: Abubuwan da aka haɗa daban-daban, gami da tsarin tallafi, matsewa, da abubuwan sanyawa, ana kera su daidai ta amfani da mashin ɗin CNC da sauran fasaha na musamman.Welding da Haɗuwa: ƙwararrun masu walda da ƙwararrun ƙwararrun masana suna haɗa abubuwan haɗin gwiwa, suna tabbatar da cewa sun dace tare daidai da aminci.Gwaji: Kayan aikin yana fuskantar gwaji mai ƙarfi don tabbatar da ya dace da daidaitawa da juriyar da ake buƙata don ingantaccen walda.Wannan ya haɗa da gwada kayan aikin abin hawa.Calibration: An daidaita madaidaicin don tabbatar da cewa ya kasance cikin cikakkiyar jeri kuma yana riƙe amincin tsarin sa.4. Gudanar da Ƙarfafawa: Tsayar da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun kayan aiki yana da mahimmanci: Bincike: Ana gudanar da bincike na yau da kullum don tabbatar da daidaito, karko, da kuma aiki na kayan aiki na kayan aiki.

Duban Haƙuri: Ana aiwatar da ma'auni daidai da gwajin haƙuri don tabbatar da cewa ƙayyadaddun ya cika ka'idodin da ake buƙata.

Tabbatar da Daidaitawa: An tabbatar da kayan aiki don tabbatar da cewa suna kiyaye daidaitattun jeri da daidaitawa don taro.5. Matsayi a cikin Masana'antar Motoci: Kayan aikin walda na kera suna da alaƙa da tsarin masana'antar kera: Chassis Welding: Gyaran gyare-gyare yana tabbatar da daidaitaccen daidaitawar kayan aikin chassis, gami da sassan firam da abubuwan dakatarwa.Welding Panel: Suna riƙe da sassan jiki, kamar ƙofofi, murhu, da fenders, a daidaitattun wurare don walda, suna ba da gudummawa ga ingantaccen tsarin abin hawa.Welding Seam: Ana amfani da gyare-gyare a cikin walda na seams, gidajen abinci, da haɗin gwiwa don ƙirƙirar haɗin gwiwa mai ƙarfi da aminci.

Welding Automation: A yawancin lokuta, ana haɗa kayan aikin walda tare da ƙwayoyin walda na mutum-mutumi don samarwa ta atomatik, ƙara haɓaka aiki da daidaito.6. Keɓancewa don Masu Kera Motoci: Masu kera kayan aikin walda na keɓaɓɓu sau da yawa sun ƙware wajen ƙirƙirar kayan aiki na yau da kullun waɗanda ke dacewa da buƙatun musamman na masu kera motoci.An ƙera waɗannan kayan aikin don saduwa da ƙayyadaddun ƙa'idodi da buƙatu na masana'antu, kuma ana iya daidaita su don ƙirar abin hawa daban-daban a cikin layin samfuran masana'anta.A ƙarshe, na'urorin walda na mota sune muhimmin sashi na tsarin kera motoci.

Magani (Sabis na Magani na Turnkey)

Jiki A Tsarin Taro Na Farko:

1, Cikakken Layin Welding Jikin Mota

2, Tsaya KadaiSalon walda

Farashin CCBWalda Fixture, Wurin Wuta Pan ASSY walƙiya Fixture, Wheelhouse ASSY Welding Fixture, AB Ring ASSY AB Welding Fixture, Seat ASSY Welding Fixture, Front Seat Cross Member Welding Fixture, Front End ASSY Welding Fixture, Dash Panel ASSY Welding Fixture, Cowling ASSY Welding Fixture, Cowling ASSY Welding Welding Fixture manufacturer, zane kamfanin da factory.

Tsarin Gudanar da ISO Don Tsarin Welding

Tawagar Gyaran Welding

Amfaninmu

1.Rich gwaninta a cikin masana'antu ta atomatik da gudanar da harkokin kasuwanci.

2.One Tsayawa Sabis don kayan aiki na stamping, duba kayan aiki, kayan aikin walda da sel don cimma lokaci da ceton farashi, dacewa da sadarwa, don haɓaka ribar abokin ciniki.

3.Professional injiniyoyi tawagar don kammala GD & T tsakanin guda part da taro bangaren.

4.Turnkey Solution Service-Stamping Tool, Checking Fixture, Welding Fixtures and Cells with one team.

5.Karfafa iyawa tare da goyon bayan fasaha na duniya da haɗin gwiwar haɗin gwiwa.

6.Big iya aiki: Dubawa Fixture, 1500 sets / year; Welding Fixture and Cells, 400-600 sets / year;Kayayyakin Hatimi, saiti 200-300 / shekara.

Muna da ma'aikata sama da 352, 80% waɗanda manyan injiniyoyi ne na fasaha.Kayan aiki na kayan aiki: 130 ma'aikata, Welding kayan aiki division: 60 ma'aikata, Dubawa rarraba: 162 ma'aikata, Muna da sana'a tallace-tallace & aikin management tawagar, dogon lokaci sabis na kasashen waje ayyukan, daga RFQ zuwa samarwa, kaya, bayan-tallace-tallace, mu tawagar zai iya magance duk matsalolin abokan cinikinmu cikin Sinanci, Turanci da Harshen Jamusanci.

Kwarewar Manyan Ayyuka Na Wayoyin Waya Da Kayan Walda

| Babban Ayyukan Gyaran walda (2019-2021) | |||||

| Abu | Bayani | Nau'in | Sunan aikin | Qty(Saiti) | Shekara |

| 1 | Farashin CCB | Arc Welding | Saukewa: MEB31 | 60 | 2019-2021 |

| 2 | Farashin CCB | Arc Welding | Farashin MEB41 | 10 | 2020 |

| 3 | Farashin CCB | Arc Welding | Farashin 316 | 4 | 2020 |

| 4 | Farashin CCB | Arc Welding | Farashin T6 | 8 | 2021 |

| 5 | Farashin CCB | Arc Welding | ISUZU RG06 | 3 | 2020 |

| 6 | Farashin CCB | Arc Welding | Bakar, BSUV | 6 | 2020 |

| 7 | Farashin CCB | Arc Welding | Bcar, BCAR | 7 | 2020 |

| 8 | Falo Pan WF | Sopt Welding | SK326/0RU_K Karoq RU | 15 | 2019 |

| VW316/5RU_K Tarek RU (19003) | |||||

| 9 | WS Spring Link WF | Arc Welding | WL/WS | 4 | 2019 |

| 10 | Ƙwaƙwalwar Maɓalli WF | Arc Welding | WL/WS | 12 | 2019-2021 |

| 11 | Gabatarwar WF | Arc Welding | VW281 | 14 | 2019 |

| 12 | Farashin WF | Arc Welding | ISUSU RG06 | 18 | 2019 |

| 13 | SL ASY da MBR da EXT ASY | Spot da Arc Welding | Farashin P703 | 25 | 2019-2021 |

| 14 | CCB WF da Ƙwayar Ƙaƙwalwa | Arc Welding | ISUSU RG06 | 6 | 2020 |

| 15 | Wurin zama na gaba memba WF | Sopt Welding | Volkswagen AG MEB316 (20001) | 4 | 2020 |

| 16 | Floor Pan WF da Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 1) | 18 | 2020 |

| 17 | Wheel House WF da Grippers | Arc Welding | Ford BX755 (19018) | 6 | 2020 |

| 18 | AB Ring WF da Grippers | Arc Welding | Ford BX755 (19018) | 14 | 2020 |

| 19 | Dash Panel WF da Grippers | Sopt Welding | Afirka ta Kudu Ford T6 (17028-1) | 10 | 2020 |

| 20 | Cowl WF da Grippers | Spot Welding | Afirka ta Kudu Ford T6 (17028-3) | 6 | 2020 |

| 21 | Ƙarshen WF na gaba da Grippers | Spot da Arc Welding | Afirka ta Kudu Ford T6 (17025) | 10 | 2020 |

| 22 | Rocker WF da Grippers | Spot Welding | Afirka ta Kudu Ford T6 (19029) | 8 | 2020 |

| 23 | Floor Pan WF da Grippers | Sopt Welding | AUDI/ PORSCHE PPE 41(19017 Phase 2) | 63 | 2021 |

| 24 | Rear Bumper da Chassis WF | Arc Welding | Ford P703&J73 | 36 | 2020-2021 |

| Manyan Ayyukan Gyaran walda (2022) | |||||

| Abu | Bayani | Nau'in | Sunan aikin | Qty(Saiti) | Shekara |

| 25 | Ƙarfafa Tashar Tsakiyar WF | Sopt Welding | Farashin VF36 | 8 | 2022 |

| 26 | Floor Pan WF da Grippers | Sopt Welding | AUDI/PORSCHE PPE 41(19017 Phase 3&4) | 39 | 2022 |

| 27 | Falo Pan WF | Sopt Welding da Hasashen walda | Ford P703 PHEV | 29 | 2022 |

| 28 | Floor Pan WF da Grippers | Sopt Welding | Porsche E4 Floor Pan (21050) | 16 | 2022 |

| 29 | Ramin bene WF | Alamar Laser | Ramin bene na VW (21008) | 2 | 2022 |

| 30 | Kujerar ASSY WF da Kayan aiki | Arc Welding | BYD Seat ASSY | 40 | 2022 |

| 31 | Falo Pan WF | Spot da Arc Welding | Ford Refurbishment | 24 | 2022 |

| 32 | Farashin CCB | Arc Welding | VW Cyclone CCB (21037) | 10 | 2022 |

| 33 | Farashin CCB | Arc Welding | VW MQB37(22022) | 16 | 2022 |

| 34 | A&B-Pillar WF | Spot Welding | Saukewa: GS2203 | 8 | 2022 |

| 35 | Robot Cell Base | NA | VW Cyclone | 4 | 2022 |

Cibiyar Kayyade Walƙiya Fixture

Za mu iya gina kowane nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i nau'i) wanda ya haɗa da girman girman girman kamar yadda muke da manyan Injin CNC.Tare da nau'ikan kayan aikin injiniya iri-iri kamar niƙa, niƙa, injunan yankan waya da injunan hakowa, za mu iya sarrafa tsarin sarrafawa daidai da daidai.

25 sets na CNC tare da 2 motsi yana gudana

1 Saitin 3-Axis CNC 3000*2000*1500

1 Saitin 3-Axis CNC 3000*2300*900

1 Saitin 3-Axis CNC 4000*2400*900

1 Saitin 3-Axis CNC 4000*2400*1000

1 Saitin 3-Axis CNC 6000*3000*1200

4 Saitin 3-Axis CNC 800*500*530

9 Saitin 3-Axis CNC 900*600*600

5 Saitin 3-Axis CNC 1100*800*500

1 Saitin 3-Axis CNC 1300*700*650

1 Saitin 3-Axis CNC 2500*1100*800

5 Axis CNC - Na'ura

4 Axis CNC - Na'ura

Welding Fixture Assembly Center

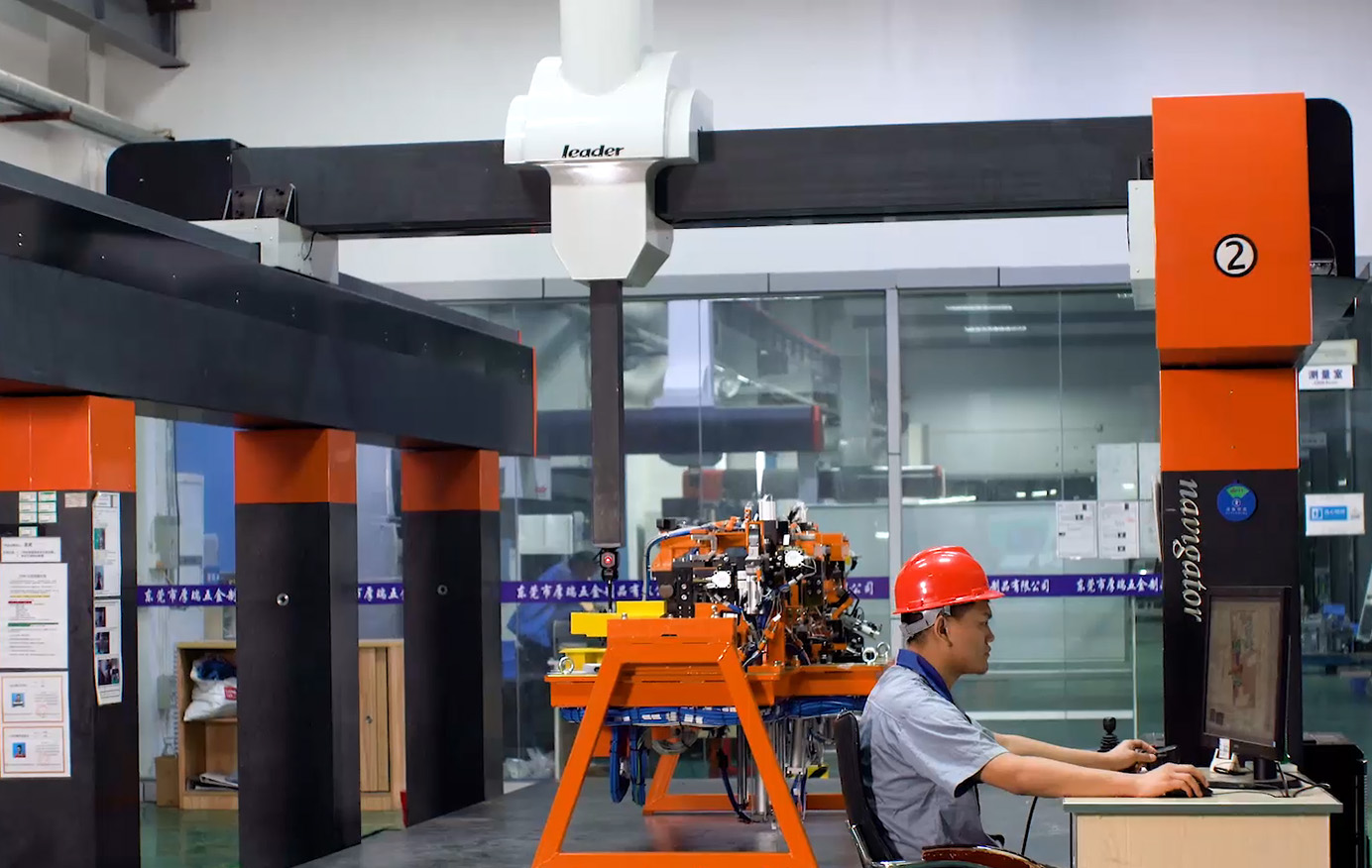

Cibiyar Aunawa ta CMM Don Gyaran Welding

OMa'aikatan da aka horar da su za su kula da kowane lokaci a cikin kowane shirin da muke da shi.Za mu iya yin kowane buƙatu daga abokin ciniki, don samun babbar gamsuwa a cikin CMM kuma.

Saituna 3 na CMM, Sau 2/rana (hrs 10 a kowace rana Litinin-Sat)

CMM, 3000*1500*1000 , Jagoran CMM, 1200*600*600

CMM, 500*500*400, Hexagon 2D Projector, Taurin Gwajin

.png)

.png)