Duba kayan aiki, kuma aka sani dakayan aikin dubawa or ma'auni, zo a cikin nau'i-nau'i daban-daban, kowannensu an tsara shi don dacewa da ƙayyadaddun masana'antu da bukatun sarrafa inganci.Ana amfani da waɗannan kayan aikin don tabbatar da ko sassa ko sassan sun cika ƙayyadaddun da ake buƙata.Ga wasu nau'ikan kayan aikin dubawa gama gari:

- Ma'aunin Sifa: Ana amfani da ma'aunin sifa don tantance ko wani siffa ta musamman a wani bangare ya cika takamaiman ka'idoji.Sau da yawa ana tsara su tare da fasalin go/no-go, inda aka karɓa ko aka ƙi sashin dangane da ko ya dace da kayan aiki ko a'a.Ana amfani da waɗannan ma'aunin don fasali kamar diamita na rami, faɗin ramin, ko zurfin tsagi.

- Ma'auni na Kwatanta: Ana amfani da ma'aunin kwatancen don kwatanta sashe da babban ɓangaren tunani ko ma'auni.Suna da amfani don auna daidaiton girma da kuma tantance bambance-bambance daga ƙayyadadden ma'auni.

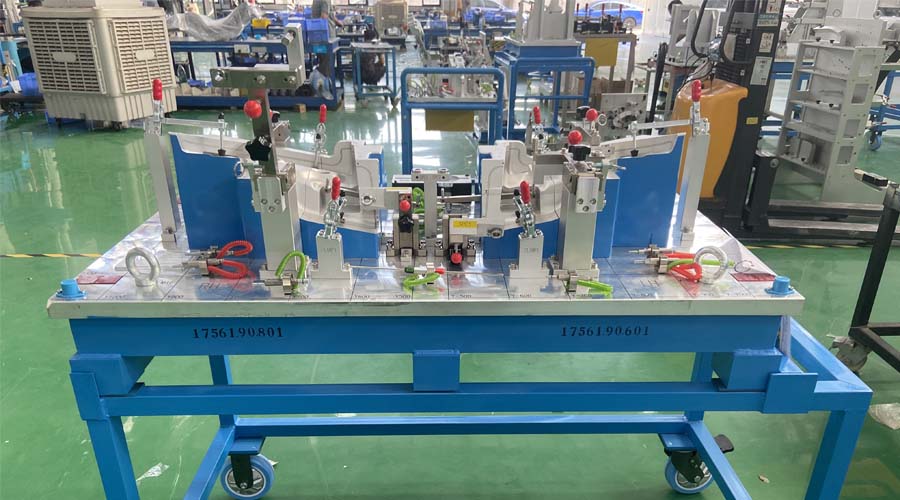

- Ma'aunin Aiki: Ma'aunin aiki yana tantance aikin sashe ta hanyar kwaikwayon yanayin aikinsa.Ana amfani da waɗannan na'urori sau da yawa don bincika haɗin abubuwan haɗin gwiwa don tabbatar da dacewa da dacewa, sharewa, da aiki.

- Ma'aunin Ma'auni: An tsara ma'auni na taro don tabbatar da daidaitaccen haɗuwa na abubuwa da yawa.Suna tabbatar da cewa abubuwan da aka gyara sun dace tare kamar yadda aka yi niyya kuma suna saduwa da abubuwan da ake buƙata.

- Gap and Flush Gauges: Waɗannan ma'aunai suna auna rata ko raɗaɗi tsakanin saman biyu akan wani sashi.Ana amfani da su da yawa a masana'antar kera motoci don tabbatar da daidaiton panel da gamawa.

- Ma'aunin Ƙarshen Sama: Ƙirar ƙarewar saman tana auna sassauƙa da santsi na wani ɓangaren.Waɗannan ma'auni suna da mahimmanci a cikin masana'antu inda ƙarshen saman ya zama ma'aunin inganci mai mahimmanci.

- Siffofin Gauges: Ana amfani da ma'aunin ƙira don auna hadaddun geometries, kamar masu lankwasa, kwane-kwane, ko bayanan martaba.Suna tabbatar da cewa siffar ɓangaren ya dace da ƙayyadaddun da ake buƙata.

- Frames Reference Frames: Datum fixtures suna kafa tsarin daidaitawa dangane da ƙayyadaddun datum (maki, layi, ko jirage).Waɗannan kayan gyara suna da mahimmanci don auna daidai fasali akan sassa bisa ga juriyar jumhuriya.

- Ma'aunin Cavity: Ana amfani da ma'aunin ramuka don duba girman ciki da fasalulluka na kogo, kamar bores, ramuka, da matsuguni.

- Ma'aunin Zaren: Ma'aunin zaren yana auna girma da jurewar sifofin zaren, yana tabbatar da zaren da ya dace da dacewa.

- Go/No-Go Gauges: Waɗannan gyare-gyare ne masu sauƙi tare da gefen tafi da babu tafiya.Ana karban bangaren idan ya dace da bangaren tafi kuma a ki yarda idan ya dace da bangaren babu tafiya.

- Ma'aunin Bayani: Ma'aunin bayanan martaba suna tantance bayanin martabar wani yanki, tabbatar da cewa ya yi daidai da sifar da aka yi niyya.

- Ma'aunin tuntuɓar lamba da waɗanda ba a tuntuɓar ba: Wasu na'urori suna amfani da lamba ta jiki don auna fasali, yayin da wasu ke amfani da hanyoyin da ba na sadarwa ba kamar Laser, firikwensin gani, ko kyamarori don auna girma da saman ba tare da taɓa ɓangaren ba.

Waɗannan ƴan misalan ne kawai na nau'ikan kayan aikin dubawa da ake amfani da su a cikin masana'antu da matakan sarrafa inganci.Zaɓin nau'in kayan aiki ya dogara da takamaiman buƙatun sassan da ake dubawa da ƙimar ingancin masana'antu.

Lokacin aikawa: Agusta-15-2023

.png)

.png)