Haɗin kai guda uku, wanda kuma ake kira girma, inji ne don auna daidaito, wanda ake kira CMM.Yana da ingantaccen kayan auna ma'auni wanda aka haɓaka a cikin 1960s.Ya fito ne saboda ingantaccen kayan aiki na kayan aikin injin atomatik da kayan aikin injin CNC, da kuma buƙatar kayan aunawa da sauri da aminci don sarrafa sassa masu siffa da ƙari.

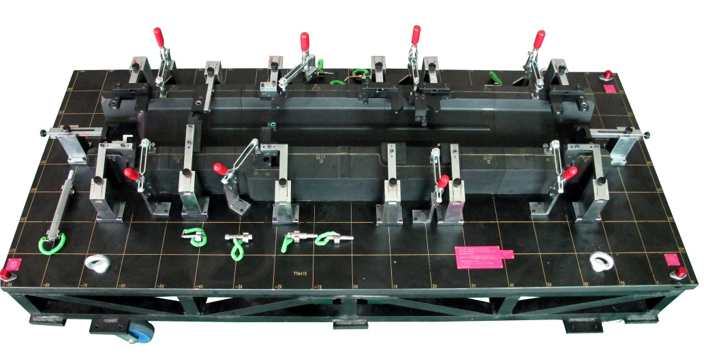

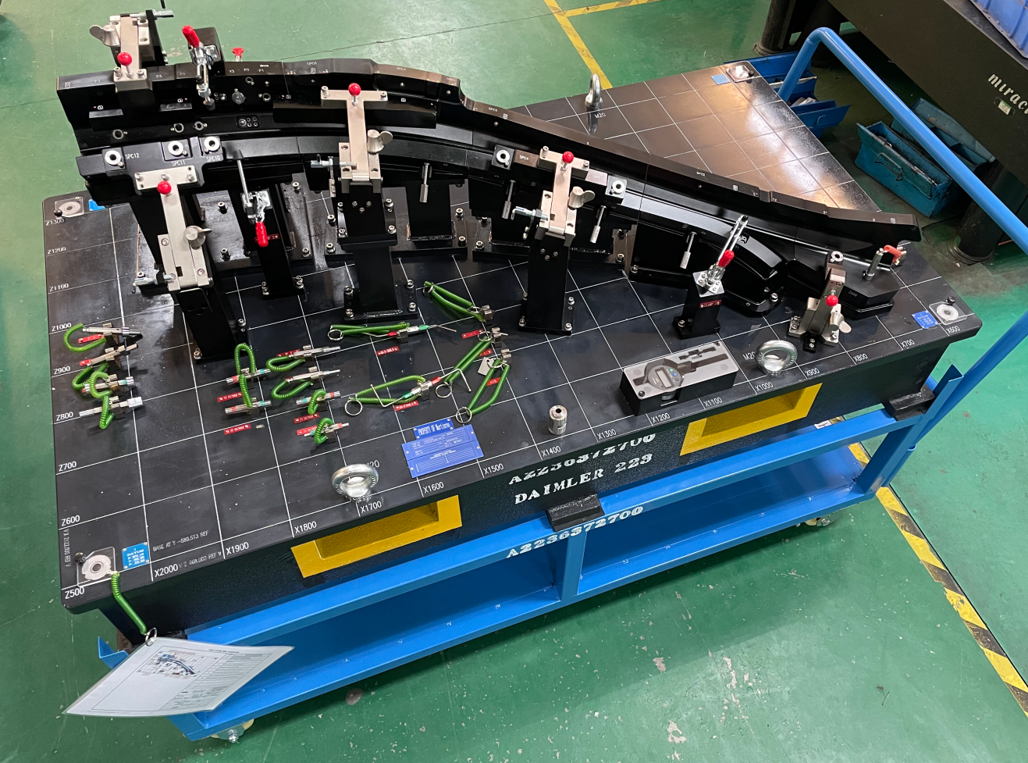

A halin yanzu, an yi amfani da ma'aunin daidaitawa guda uku a masana'antu daban-daban kamar masana'antar kera, masana'antar mota, masana'antar lantarki, masana'antar sararin samaniya, da sauransu, kuma ya zama kayan auna madaidaicin madaidaicin ma'auni don duba masana'antu na zamani da sarrafa inganci.Don gages ɗin mu na musamman waɗanda ba daidai ba, ma'aunin daidaitawa guda uku kayan aikin gwaji ne wanda babu makawa.Bayan mun sami zane-zane na samfurin abokin ciniki da kuma tsara tsarin gage wanda ya dace da bukatun samfurin kuma abokin ciniki ya gamsu, ya zama dole.Fara matakan sarrafawa a cikin mataki na gaba, sannan muna buƙatar amfani da ma'aunin haɗin gwiwarmu guda uku, saboda daidaiton na'urar kanta tana da girma sosai, don haka amfani da ita don gwada daidaiton kowane ɓangaren gage ɗinmu, don gage ɗin kanta ƙari. yana tabbatar da daidaiton kayan aikin mu na dubawa.Alal misali, wasu matsayi na gage, flatness da profile sun hada da wasu sassa na mota.Dukkanmu zamu iya samun ainihin girman ta hanyar gano ma'aunin daidaitawa

Lokacin aikawa: Maris-06-2023

.png)

.png)