Tare da saurin ci gaban masana'antar kera motoci, mutane suna da buƙatu mafi girma kuma mafi girma don aiwatarwa, dogaro da ƙayataccen fa'idodin mota.Zana I-dimbin yawa shine mafi mahimmancin tsari a cikin tsarin samar da sassan jiki.Ko ƙirar sa ta dace zai ƙayyade Kai tsaye yana shafar ingancin fa'idodin mota da kuma ci gaban ci gaban sabbin samfura.Don haka,TTMyayi nazarin tsarin zane na bangarori na mota, wanda ke da amfani don gajartamtsara lokaci, inganta bayyanar ingancin bangarori, da haka inganta gasa na kamfanoni.Wannan takarda ya fi gabatar da tsarin zane na gefen bangon gefen waje.

1.1 Abubuwan da aka saba amfani da su don bangarorin gefe

Tsarin kafa na gefen bangon gefen gabaɗaya matakan 4-5 ne (ban da blanking).Domin tabbatar da ingancin samfurin noodle da kuma rage wahalar cirewa, yawancin ganuwar gefen an kammala su a matakai biyar.Saboda hadadden siffar bangon gefe da zurfin zane mai zurfi, kayan da aka saba amfani da su sune DC56D + Z ko DCO7E + Z + pre-phosphating tare da ingantattun kayan aikin injiniya, kuma kauri na kayan gabaɗaya 0.65mm, 0.7mm, da 0.8mm ku.Idan aka yi la'akari da rigakafin tsatsa da tsattsauran ra'ayi da tsari na sassa, abin da aka fi so shine DCDC56D+Z/0.7t.A lokaci guda, ƙaddamar da iyaka na ƙofar ƙofar gefen yana da dangantaka mai kyau tare da kusurwar R na mummunan layin kayan aiki.Ƙananan kusurwar R na mummunan abu a ƙofar ƙofar, mafi sauƙi iyakar ita ce fashewa.

1.2 Jagorar hatimi na gefen bangon waje

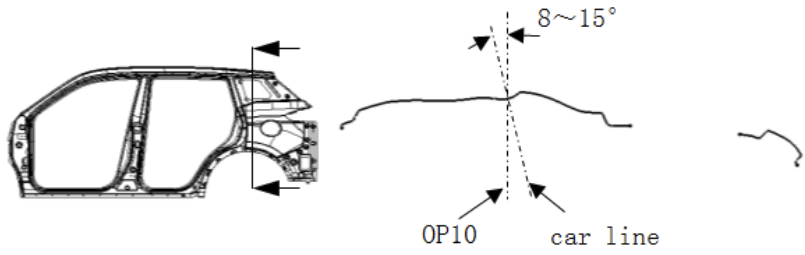

Gabaɗaya la'akari da tsarin ƙirƙirar bangon bangon waje, gabaɗaya jagorar hatimi na gefen bangon gefen bango yana a kusurwar 8-15 ° tare da jagorancin Y na jikin abin hawa.

1.3 Ƙarin maki don kulawa a cikin tsarin bangon bangon waje

1.3.1 Abubuwan kulawa don saita ƙarin siffar babban ɓangaren B-ginshiƙi

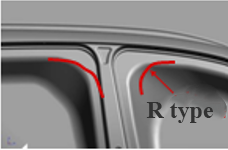

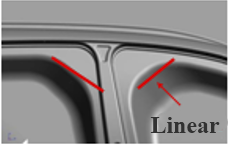

Akwai hanyoyin saiti guda biyu don zana sauran naman a saman kusurwar B-ginshiƙi.Ɗayan shine zana layin rabuwa na naushi a kusurwar naushin kusa da siffar samfurin, wato, nau'in R.Wannan siffar sauran naman naman zai iya rage matsayi na kusurwar sama.Za'a iya daidaita kauri da raguwa na kayan don hana fashewa.Ɗayan shine saita layin rabuwa na naushi a kusurwar zanen zane zuwa siffar layi, wato, layi madaidaiciya.Wannan nau'i na sauran naman naman zai iya inganta tsari na kusurwa na sama kuma ya dakatar da saman saman ɓangaren B-ginshiƙi ya lalace.

1.3.2 Mahimman hankali don saita ƙarin siffar tsari a wurin buɗe kofa

Layin rabuwa a buɗe kofa ya kamata ya canza daidai gwargwado gwargwadon yiwuwa, kuma canjin bai kamata ya kasance mai kaifi ko juyawa ba

1.4 Saitin zanen bead a gefen bangon bangon waje

Saboda hadadden siffar bangon gefe, don sarrafa yadda ya kamata a sarrafa kayan aiki a kowane bangare, ana amfani da haƙarƙari biyu gabaɗaya.Don hana zanen zane daga rarrafe cikin saman samfurin kuma ya shafi ingancin samfurin, nisa tsakanin zanen zane da samfurin kusa da bakin kofa ya kamata a fadada, sannan a daidaita matsayin zane ta hanyar nazarin kwaikwaiyo na CAE. amfani da Autoform software.Zane a cikin buɗe kofa ya kamata ya zama santsi kamar yadda zai yiwu, kuma kusurwar R ya kamata ya zama babba gwargwadon yiwuwa.

Lokacin aikawa: Mayu-24-2023

.png)

.png)